The Ultra-pure Water System

13 processes for the ultra-pure water system(Water Resistivity >17MΩ、Total plate count ≦30 CFU/ml)

The ultra-pure water system

The critical point to the best quality of products

3dL's ultra-pure water system, which exceeds the quality requirements of medical standard, reduces the side effects and the interference from various chemical elements, and make the water to be used in its most natural and cleanest state for the production of excellent skin care products.

The best quality of water is the excellent choice for making your skin more beautiful.

Pre-processing system

Hygiene storage tank

Grade 1 and 2 heat sterilization RO water systems

1`st electric de-ionization system

UV sterilization equipment for the supply and return of water

PRODUCTION

Facial Masks-Automated Production Management

From the CCD testing of cloth membrane, cutting, folding, packaging, the production of essences the filling of essences, sealed to the finished products and printing to complete a single packet—the precise and efficient integrated process of production eliminates any possibility of the contamination for every single mask, and provides consumers the high quality of masks they can feel safe and love to use it.

Process 1: Cloth membrane dispenser

Process 2: CCD testing

Process 3: Cutting/Folding/Packaging

Process 4: The filling of essence / Sealed and printing

High-resolution, fast and robust CCD camera

CCD Camera

High precision testing equipment

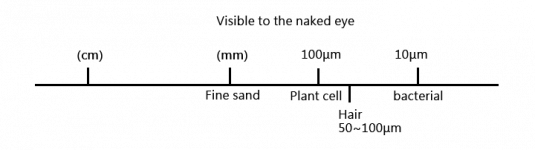

Using CCD detection can immediately and accurately catch the small black spots that are on the mask sheet invisible to the naked eye.

- Sensitivity: 0.15 mm (100 μm)

- About one hair diameter can be detected.

- Reduce the rate of false judgments (avoid repeated inspections by operators)

- Automatically grab black spots

- Avoid external pollution

INTELLIGENT

Skin care products – the fully automatic intelligent equipment of production

The construction of a fully automated intelligent production system of skin care products not only enhances the efficiency of production, but also maintains a safe, hygienic, dust-free, and low-temperature operation to ensure the best quality of the skin care products.

Six tubes filling machine

Vacuum Emulsifying equipment

The Green & Smart Factories

The three bases of production of skin care

Compliance with ISO International Standard

Granted are the ISO 22716 authorization, Taiwan GMP and multiple international recognitions. Equipped with the auto-production of sheet masks and the packaging system in 2008. The ultra-pure water system is compatible with the standard of pharmaceutical regulation. Possessing class 100k clean production rooms. All 3dL products are under scrupulous examinations to ensure the best quality.